Sewing for Money

Like every girl in Ontario in the 60’s I took Home Economics in grades 7 and 8. Each term was devoted to cooking or to sewing. Our Home Ec room boasted 4 compact kitchens which we used in teams and a sewing room with a machine for everyone. I still remember my embarrassment when the Home Ec teacher measured us so we could go purchase a pattern. Each student approached her desk and she recorded their measurements on a pad. I puffed up my chest as big as I could, being completely flat chested. “Breathe Elinor, breathe” was her sardonic comment. Mortification.

The pattern was for a simple shift dress with a zipper up the back. Somehow, when using a seam ripper to open the zipper placket, I went right through the zipper end and almost cut the back in half. Numerous rows of sewing back and forth across the rip at least held the dress together. In the assembly to show our parents our creations I sidled across the stage sideways, trying never to show the back of my dress. I’m sure I saw my mother cringe.

My real interest in sewing began when, at 15, mom offered me an allowance of $15 a month to buy all my own clothing. I was ecstatic! I became the frequent visitor of every second hand store in town. I started altering things on my mother’s sewing machine to make them uniquely mine. Then I discovered that fabric was much cheaper than clothing. I definitely needed my own sewing machine. At 17 I purchased a Bernina ‘Mini-Matic’, the Cadillac portable machine of its day. Friends thought I was nuts…why buy a $300 machine when you could buy one for $100. Undaunted I set my sights on the Bernina and sold some Bell Telephone stocks I had received from my grandparents. I still use that machine today and it still runs flawlessly.

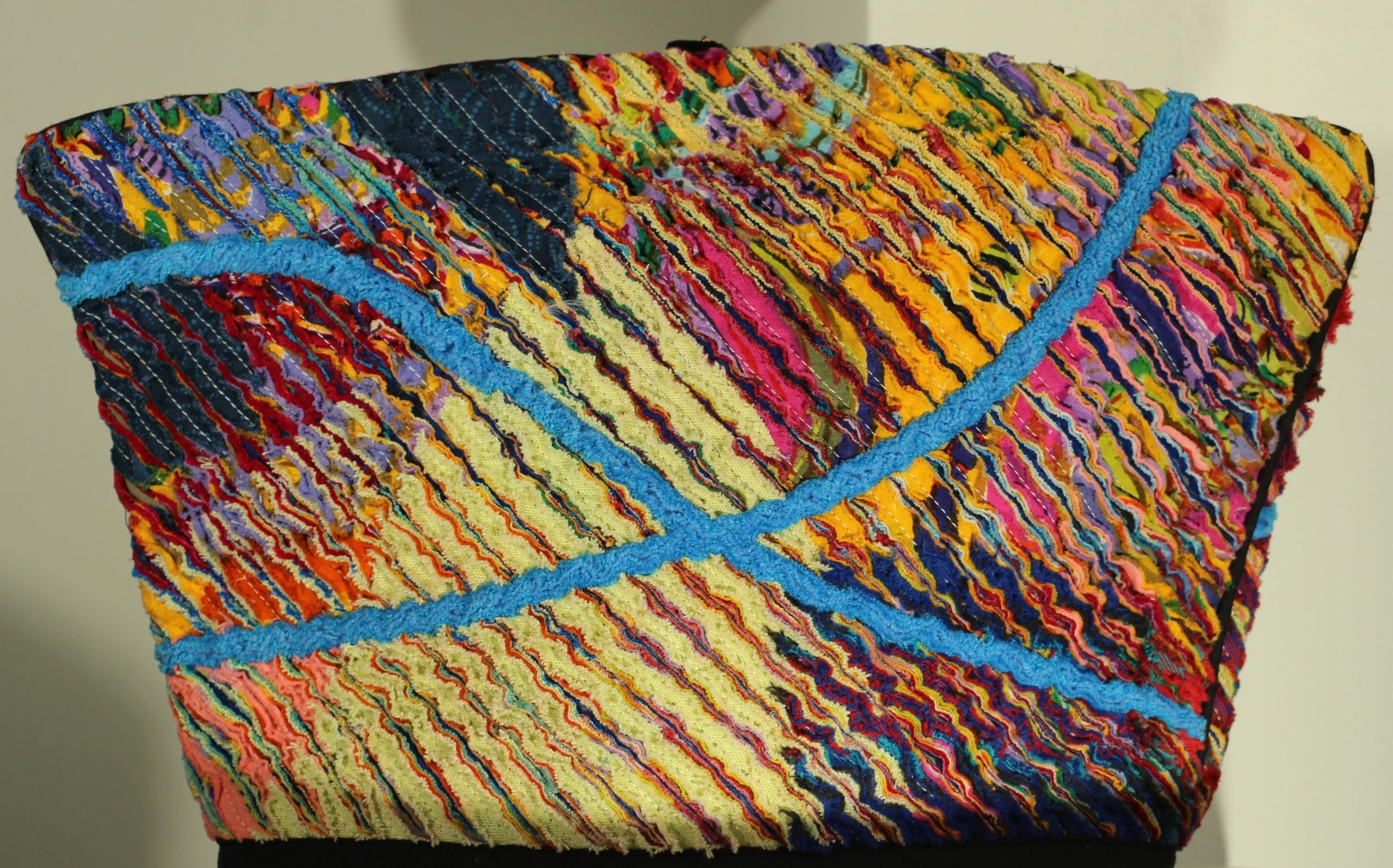

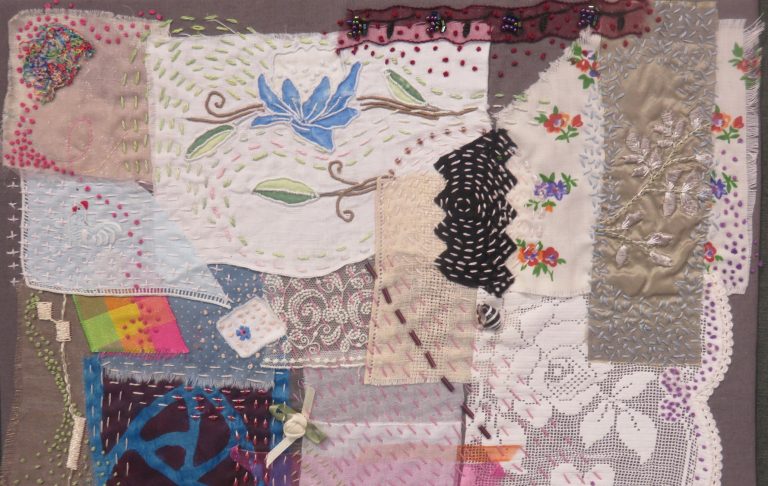

There is fashion and then there is style. When you are altering used clothing and sorting through fabric clearance bins you really have to let go of the latest fad. Instead one must celebrate the unusual, the esoteric and the occasional complete failure. All of this I embraced and was never really caught up in desiring a particular brand, or style. I thought standing out was better than fitting in.

When I was 18 and by then an avid sewer I was approached by a downtown store called Morningstar to make a dozen size medium flannel nightgowns. Morningstar was one of several stores, opened in the early seventies, by new younger entrepreneurs in Kingston, catering to the youthful ‘hippies’ of the town. Tara Natural Foods, Printed Passage Books, Scarecrow Coffeehouse and The Sunflower Restaurant all started in that seventies era.

I had absolutely no experience in the business of sewing. But Morningstar couldn’t find the look and quality they wanted through their suppliers. I couldn’t believe my luck! An income from sewing! Off I went to the many fabric stores that Kingston supported at that time and bought loads of fabric, enough for two gowns in each print. I visited Whitney’s, The Mill End, S&R and Fabricland, all located in downtown Kingston.

The cutting out of the first few nightgowns went smoothly. My sewing style at the time was to proceed at breakneck speed, often without reading the instructions, until a collection of mistakes stopped me in my tracks. My response was to throw the offending item in the back of my closet and try something else. After several of the Morningstar nighties met this fate I realized that the enormous profit I had anticipated was lying on that same closet floor, in garments requiring unpicking and fixing. The value of slowing down, of understanding the way one step led to another, of fixing errors promptly before building on top of them became abundantly clear.

I learned something wonderful in that learning process. I actually loved the process of construction, not just the end result. Completing each step properly was satisfying in its own right and ultimately led to a better end product. I was much happier. Many years later I came to value the process of altering each garment so it actually fit the wearer. Fitting information is not usually included with patterns and is probably the most important detail of all. That the thing fits! Eventually one learns every little difference between standard sizing and one’s own individual form. Fit is the main reason most sewers are dissatisfied.

In 1972, when I was 20, I was amazed when my friend Susan Quinn invited me to put some clothing in her tiny boutique, Dudley, in downtown Kingston on Brock St. Her shop had previously been the Opportunity Shoppe, a second hand charity store run by the Kingston Symphony Association. Familiar to me and well loved. Susan maintained a small stock of finished garments but most of her income came from commissions. Customers would see a garment they liked, go buy the fabric they wanted and Susan would make the item up for them. My role would be to make things that might sell ‘off the rack’ in her store. At the time loose unbleached cotton pullover shirts were all the rage for men and women. Unbleached cotton was cheap and fitting not required. They sold as fast as I could make them.

Sewing for money had helped me focus on details and I had become a very competent sewer. I was ready for a new challenge. I set my sights on a set of matching cowboy shirts with intricate pocket details and fitting required. Destined for my boyfriend’s 5 piece country band. They were a ton of work, paid a pittance, but they looked great and they fit.

That was all over fifty years ago. I have been a sewer, a designer, and an unpicker ever since. What do I love? Attention to detail, orderly progress, making it fit, and dreaming of my next project.